High performance Ceramic ball valve apply to fly ash application

- Description

- Inquiry

High performance Ceramic ball valve apply to fly ash application

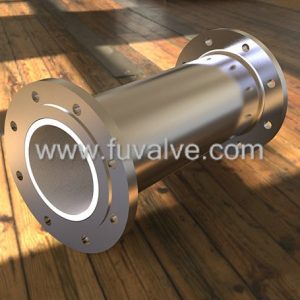

As the fly ash handling system, high speed fly ash is extreme abrasive, and abrasion is the main problem for pipe valves and elbows. Generally soft seated and metal seated ball valves cannot last more than 3 months, frequent replacement and maintenance of the valves consumes too much manpower and cost, and also had a negative impact for the pneumatic conveying system.

.jpg)

High performance Ceramic ball valve apply to fly ash application

FUVALVE has many and many successful experience in ceramic valves supply to coal fired power plants and steel plants, FUV ceramic ball valves have excellent performance and reputation.

.jpg)

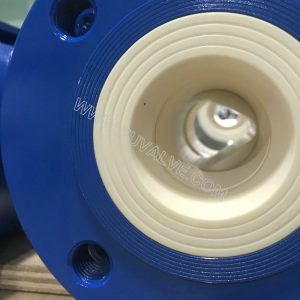

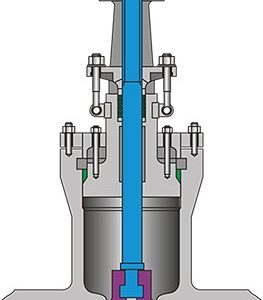

Advantages of structural ceramic ball valves include hi-economy, long life (2~4 times of Titanium Valves), increase resistance to corrosion, high temperature, wear and erosion etc.. They are commonly used in transportation systems of various acid, alkaline or saline gases, solutions, high working temperature steams and slurry, in the lines of oil industry, metallurgy, paper making, power station, refinery, etc. Structural ceramic ball valves are the ideal substitute for titanium and monel valves in corrosive environments. There are four types of driving performances, manual, pneumatic, pneumatic-spring return and electric. Various special valves can be designed on demand. Furthermore, various high wear-resistant, corrosion-resistant and high temperature-resistant ceramic components, hydraulic pressure sealing components can be provided as well.

Typical Applications:

In many corrosive or/and abrasive applications, PTFE or PFA lined ball valves and metal seated ball valves are used, but limited to the material, these PTFE or PFA lined ball valves and metal seated valves cannot last for a long time due to severe abrasion and corrosion. Ceramic ball valve have excellent performance and much longer life time than soft seated and metal seated ball valves in most corrosive and abrasive applications. Some typical applications listed below (but not limited to these applications) where FUVALVE Ceramic ball valve have been widely used all over the world: Silicon Powder,Alumina Powder,Dry Coal Powder,Limestone Slurry,Gypsum Slurry,Plaster,Fly Ash,Mining Ore,Coal Powder Injection,Metallurgical dust,Thermal Power plant FGD,Petroleum Solid Catalyst,TiO2 suspension with sulfuric acid,Ammonia solution with powder,Hydrochloric Acid,Liquid Chlorine,Bulk Material.