Ceramic segment ball Valve

- Description

- Inquiry

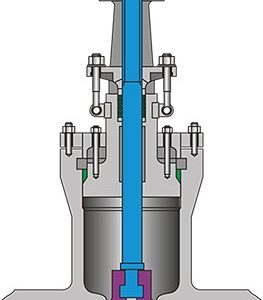

1.Straight-through type.One-way Seals and eccentric structure,the ball will separate from the body when the valve is opened,and the valve will not be blocked.

2.It’s laborsaving and rotating flexible when open and close the valve because at that time,the valve ball will separate from the seal seat and there is no contact and the torque is very low.Because of the shearing between the ball and the seat,the hard seal ceramic dome valve is self-cleaning and self-lubricating,and maintain a tight seal.

3.Ling-life service,safe and reliable.The eccentric structure of the sealing spherical surface allows automatic compensation for wear and tear to maintain the valve’s sealing per formance.

4.High abrasion resistance and corrosion resistance because of the hard-seal structure of the ceramic dome valve.

Nominal pressure:1.0-6.8MPa

Nominal Diameter:DN50-DN300

Suitable Medium:Pulp,alumina powder,coal dust,dust gas,waste residue and etc.

Note:Gas-seal Testing Pressure is 0.6MPa

Ceramic segment ball Valve

Stainless Steel lined Ceramic segment ball valves have lower flow resistance, small volume, light weight which is easy to transport and install. Fuvalve ceramic seated segment ball valves are widely used for all kinds of abrasive slurry and powder transportation.

The trim of common metal seated segment ball valve is easily abraded by gas-solid mixture and slurry containing high-hardness solids, which will cause leakage easily. Combining structure advantage of segment ball valve with excellent performance of structure ceramics, FUVALVE has developed Ceramic segment ball valves series Stainless Steel Ceramic segment ball valves.

Ceramic segment ball valves series ceramic segment ball valve is designed as flange ends. Body material could be carbon steel, stainless steel according to working conditions or per customers’ requirements. Hemispherical sealing ring and seat are structure ceramics, so that sealing face will not be eroded, abraded and corroded by medium and make sure of excellent sealing performance during long-time usage.

Performance characteristics

FUVALVE ceramic segment ball valve series ceramic segment ball valve is eccentric design. When valve is opening, Hemispherical sealing ring and seat departs, which will reduce valve torque effectively. When valve is closing, hemispherical sealing ring and seat will make a shear effect to cut off solid and fiber in the medium to avoid foreign things stuck valve or cause leakage.

Hemispherical sealing ring and seat use high performance structure ceramics. ZrO2,99%Al2O3, solid tungsten carbide, Si3N4 are optional for different working conditions.

Hemispherical sealing ring and seat sealing is sphere sealing. It makes use of advanced technology and machining equipment. After precision grinding, leakage class could reach ANSI/FCI 70-2 V.

Actuated method includes bare stem, gear, pneumatic actuator, electric actuator and so on. Yoke Interface dimensions are designed according to ISO 5211.

Applied field

ZrO2,99%Al2O3 and Si3N4 has excellent chemical stability, which can make sure that sealing face of Ceramic segment ball valves series ceramic segment ball valve will not be destroyed after long-time applying in all kinds of corrosive and abrasive medium.

Ceramic segment ball valve has huge body with one-way seal so that valve will not be stuck or leaked because of blocked medium in the valve. Eccentric structure makes sure that there is shear cut-off of solid and fibers when valve is closing.

Ceramic segment ball valves series ceramic segment ball valve has good performance for steel mill, mining, pulp and paper and environmental protection and so on.