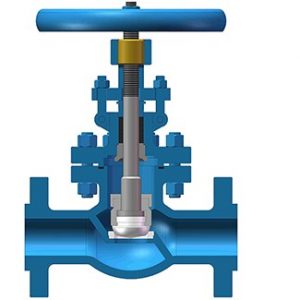

Ceramic Knife Gate Valve

Driving Mode: Manual/Electric/Pneumatic

- Description

- Inquiry

Driving Mode: Manual/Electric/Pneumatic

Performance Characteristics

1. The structure length adopts short series, light valve body, easy to install.

2. In the valve switching process, the gate will scrape the impurities on the sealing surface, clean the sealing surface, to ensure that the valve is well sealed.

3. Knife gate can cut the particles and fibers in the medium to prevent the valve from jamming.

4. Adopting the clamping structure.

5. Wedge block can provide enough thrust to ensure that the valve seals reliably.

6. The guide block can provide good guiding function.

7. According to the different media and working conditions, the wear-resistant bushings can be selected from different materials to meet the requirements of wear and scour resistance. In most cases, we use high-performance structural ceramic materials for the valve channel lining and seat materials.

8. Handwheel, bevel gear, pneumatic, electric, hydraulic, electro-hydraulic actuators can be supplied according to customers’ requirements.

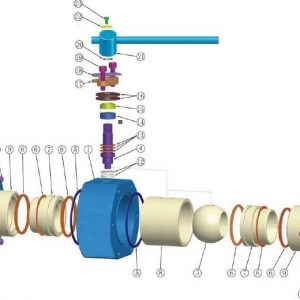

Typical Applications:

In many bulk material handling systems, such as coal fired power plant, steel plant, cereals transport system, cement transport systems, etc., generally in these applications, pneumatic conveying method is used to reduce manpower demand, and improve system efficiency and reliability. But abrasion of valves is a big problem that causes customers a lot trouble.

The valve sealing surface and flow path of these valves are destroyed seriously by high speed solid materials. FUVALVE develops Ceramic Double Disc Valves for these applications which works quite well for coal fired power plants all over the world.

Ceramic Knife Gate Valve