陶瓷刀闸阀

驾驶模式: 手动/电动/气动

- 描述

- 查询

驾驶模式: 手动/电动/气动

Performance Characteristics

1. The structure length adopts short series, light valve body, easy to install.

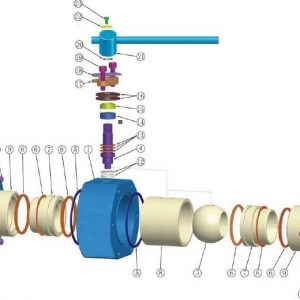

2. In the valve switching process, the gate will scrape the impurities on the sealing surface, clean the sealing surface, to ensure that the valve is well sealed.

3. Knife gate can cut the particles and fibers in the medium to prevent the valve from jamming.

4. Adopting the clamping structure.

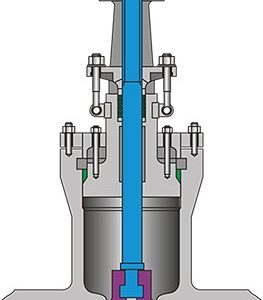

5. Wedge block can provide enough thrust to ensure that the valve seals reliably.

6. The guide block can provide good guiding function.

7. According to the different media and working conditions, the wear-resistant bushings can be selected from different materials to meet the requirements of wear and scour resistance. In most cases, we use high-performance structural ceramic materials for the valve channel lining and seat materials.

8. 方向盘, bevel gear, 气动, 电的, 液压, electro-hydraulic actuators can be supplied according to customers’ 要求.

典型应用:

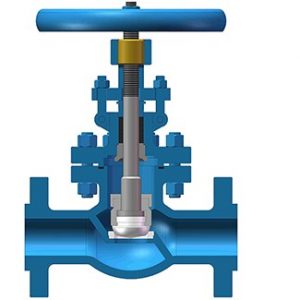

在许多散装物料处理系统中, 比如燃煤电厂, 钢铁厂, 谷物运输系统, 水泥运输系统, 等等。, 通常在这些应用中, 采用气力输送方式,减少人力需求, 并提高系统效率和可靠性. 但是阀门的磨损是一个大问题,给客户带来很多麻烦.

这些阀门的密封面和流道被高速固体物质严重破坏. FUVALVE 为这些应用开发陶瓷双盘阀,适用于世界各地的燃煤电厂.

陶瓷刀闸阀